Stud Bolt and Nuts

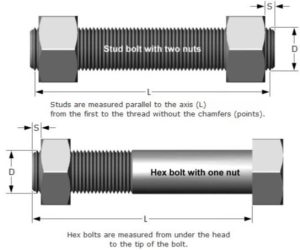

A193 B7 Stud Bolt is a bolt with threads on both ends that designed to be screwed into a fixed part at one end, and to receive a nut on the other end. In Petroleum or Chemical industry, they are prominently used for flange connection, so stud bolt used with two nuts on either side is the most common combination which replaces bolt and nut assembly.

As we know that Stud Bolts have many categories, the type for flange connection is called flange stud bolts, which has fully thread with chambered ends. The theoretical length is measured the thread. Continuous threaded stud bolt is very similar to it, except no chambered ends.

Stud Bolt and Nuts

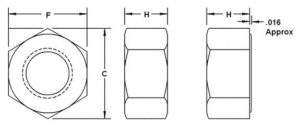

Heavy hex nuts are slightly larger and thicker than standard hex nuts. They are come in different grades and heavy pattern, and typically used for large diameter and high strength bolts. It is washer faced.

The diameter and length of bolts is according to flange type and pressure, and the quantity are depending on flange bolt hole.

Stud and Bolt

While Studs and bolts are very similar. They are both threaded fastener and belong to detachable connection. The differences between them as follow.

- Shape

Stud is an external threaded rod with one head. Bolt has thread at both ends without head.

- Usage

Mostly Studs and nuts are working together to connect two objects with through holes.

One end of bolts is screwed into the metal part with internal threaded hole, the other end is passed through the metal part with through hole, and then the nut is screwed to fasten the two or more parts together.

Bolting Dimensions for Class 300 Flanges

Bolting Dimensions for Class 300 Flanges

A105N Class 300 Flange is quite common used in industries, but this time we would like to show A193 B7 stud bolt dimensions for ASME B16.5 Class 300 Flanges.

| NPS | Diameter

Bolts inch |

Length

RF mm |

Length

RTJ mm |

No

of Bolts |

|---|---|---|---|---|

| 1/2 | 1/2 | 65 | 75 | 4 |

| 3/4 | 5/8 | 75 | 90 | 4 |

| 1 | 5/8 | 75 | 90 | 4 |

| 1 1/4 | 5/8 | 85 | 95 | 4 |

| 1 1/2 | 3/4 | 90 | 100 | 4 |

| 2 | 5/8 | 90 | 100 | 8 |

| 2 1/2 | 3/4 | 100 | 115 | 8 |

| 3 | 3/4 | 110 | 120 | 8 |

| 3 1/2 | 3/4 | 110 | 125 | 8 |

| 4 | 3/4 | 115 | 125 | 8 |

| 5 | 3/4 | 120 | 135 | 8 |

| 6 | 3/4 | 120 | 140 | 12 |

| 8 | 7/8 | 140 | 150 | 12 |

| 10 | 1 | 160 | 170 | 16 |

| 12 | 1 1/3 | 170 | 185 | 16 |

| 14 | 1 1/3 | 180 | 190 | 20 |

| 18 | 1 1/4 | 195 | 210 | 24 |

| 20 | 1 1/4 | 205 | 220 | 24 |

| 24 | 1 1/2 | 230 | 255 | 24 |

What is ASTM A193 B7 Stud Bolt?

ASTM A193 specification covers alloy steel and stainless steel bolting material of pressure vessels, valves, pipe flanges, and pipe fittings for high temperature or high pressure service, it is chromium molybdenum alloy steel and hold the strength to 1000 degrees F. Usually A193 B7 Stud Bolt are engineered to mate with 2 sets of ASTM A194 Grade 2H Heavy Hex Nuts. We will introduce later. Let’s see the bolts chemical and mechanical first.

Tensile strength and yield strength is strength indicators, elongation and reduction belong to plastic and toughness indicators.

While Tensile strength is the maximum tensile that a finished fastener can withstand before it breaks or begins to break. Tensile Load = Tensile Strength X Thread Nominal Stress Cross-Sectional Area

When the A193 B7 Stud Bolt reaches the yield strength, it has entered the plastic deformation range.

Elongation and reduction measure the deform ability before breaking.

A193 B7 Stud Bolt Chemical Composition %

| C | Mn | Si | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.37-0.49 | 0.65-1.10 | 0.15-0.35 | 0.035 | 0.04 | 0.75-1.20 | 0.15-0.25 |

A193 B7 Stud Bolt Mechanical Properties

| Diameter | Tensile Strength | Yield Strength | Elongation | Reduction | Hardness |

|---|---|---|---|---|---|

| M64 or Below | 860 Mpa | 720 Mpa | 16 | 50 | 321 HB |

| M64 to M100 | 795 Mpa | 655 Mpa | 16 | 50 | 321 HB |

| M100 to M180 | 690 Mpa | 515 Mpa | 18 | 50 | 321 HB |

A194 Grade 2H Heavy Hex Nuts

Standard A194 covers a variety of carbon steel, alloy steel and stainless steel nuts. Nuts of this specification are used for high-pressure and high-temperature conditions. They are quenched and tempered carbon steel nut. Quenching and temper are common heat treatment process.

Quenching enhance the hardness of Pipe Fittings. The main processes are heating, heat preservation and quick cooling. Cooling medium generally is brine or oil. High hardness and clear surface can be obtained with brine as the medium, but deform and crack prone to generate. Oil medium is only suitable for stable, Austenite carbon steel or Alloy Steel Fittings under A1 temperature.

Temper helps reduce brittleness and internal stress of hex nut. It can adjust mechanical properties to suit different needs. Hex nuts has high hardness and brittleness after quenching, tempering can reduce hardness and increase toughness or plasticity.

Heavy Hex Nuts Dimension Chart

Heavy Hex Nuts Dimension Chart

| Basic | Width Across Flats | Width Across Corners | Thickness | |||||

|---|---|---|---|---|---|---|---|---|

| Dia | Basic | Max | Min | Max | Min | Basic | Max | Min |

| 1/4 | 1/2 | 0.5 | 0.488 | 0.577 | 0.556 | 15/64 | 0.25 | 0.218 |

| 5/16 | 9/16 | 0.562 | 0.546 | 0.65 | 0.622 | 16/64 | 0.314 | 0.28 |

| 3/8 | 11/16 | 0.688 | 0.669 | 0.794 | 0.763 | 23/64 | 0.377 | 0.341 |

| 7/16 | 3/4 | 0.75 | 0.728 | 0.866 | 0.83 | 27/64 | 0.441 | 0.403 |

| 1/2 | 7/8 | 0.875 | 0.85 | 1.01 | 0.969 | 31/64 | 0.504 | 0.464 |

| 9/16 | 15/16 | 0.938 | 0.909 | 1.083 | 1.037 | 35/64 | 0.568 | 0.526 |

| 5/8 | 1 1/16 | 1.063 | 1.031 | 1.227 | 1.175 | 39/64 | 0.631 | 0.587 |

| 3/4 | 1 1/4 | 1.25 | 1.212 | 1.443 | 1.382 | 47/64 | 0.758 | 0.71 |

| 7/8 | 1 7/16 | 1.438 | 1.394 | 1.66 | 1.589 | 55/64 | 0.885 | 0.833 |

| 1 | 1 5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | 0.956 |

| 1 1/8 | 1 13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1 7/64 | 1.139 | 1.079 |

| 1 1/4 | 2 | 2 | 1.938 | 2.309 | 2.209 | 1 7/32 | 1.251 | 1.187 |

| 1 1/2 | 2 3/8 | 2.375 | 2.3 | 2.742 | 2.622 | 1 15/32 | 1.505 | 1.433 |

| 1 3/4 | 2 3/4 | 2.75 | 2.662 | 3.175 | 3.035 | 1 23/32 | 1.378 | 1.31 |

| 2 | 3 1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1 31/32 | 2.013 | 1.925 |

| 2 1/4 | 3 1/2 | 3.5 | 3.388 | 4.041 | 3.862 | 2 13/64 | 2.251 | 2.155 |

| 2 3/4 | 4 1/4 | 4.25 | 4.112 | 4.907 | 4.688 | 2 45/64 | 2.759 | 2.647 |

| 3 | 4 5/8 | 4.625 | 4.475 | 5.34 | 5.102 | 2 61/64 | 3.013 | 2.893 |

| 3 1/4 | 5 | 5.375 | 5.2 | 6.207 | 5.928 | 3 7/16 | 3.506 | 3.37 |

| 3 1/2 | 5 3/8 | 5.375 | 5.2 | 6.207 | 5.928 | 3 7/16 | 3.506 | 3.37 |

| 3 3/4 | 5 3/4 | 5.75 | 5.562 | 6.64 | 6.341 | 3 1/16 | 3.76 | 3.616 |

| 4 | 6 1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3 5/16 | 4.014 | 3.862 |

A194 2H Hex Nut Chemical Components %

| C | Mn | Ph | S | Si |

|---|---|---|---|---|

| 0.40 min | 1 | 0.04 | 0.05 | 0.4 |

A194 2H Hex Nut Mechanical Properties

| Size | Tempering

Temp Fahrenheit |

Proof Load

Stress, ksi |

Hardness |

|---|---|---|---|

| 1/4-1 1/2 | 850 | 175 | 248-327 |

| 1 1/2-4 | 850 | 175 | 212-327 |

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....